ST-1200 Line Receptacle Support Preparation

S-Spring

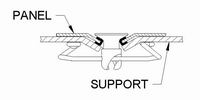

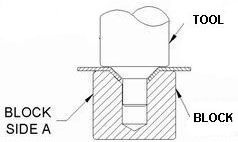

- Support Preparation for S-Spring Receptacle

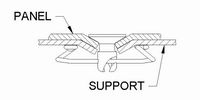

- Dimpled Support Preparation For S-Spring Receptacle (Flush Head Stud)

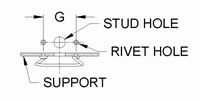

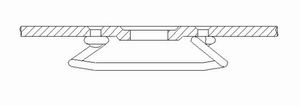

Support Preparation for S-Spring Receptacle

Stud Retainer Recessed in Panel Underside

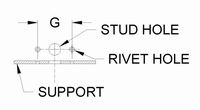

| Spring Size | Stud Hole Dia. | Dim. G ±.002 |

Rivet Hole Dia. | Rivet Hole Countersink | Rivet Shank Dia. |

| 3 | 7/32" | .625" | .097" to .100" | 3/16" dia. x 110° | 3/32" |

| 4 | 9/32" | .750 | |||

| 5 | 11/32" | 1.000" | .129" to .133" | 1/4" dia. x 110° | 1/8" |

| 65 | 15/32" | 1.375" |

|

|

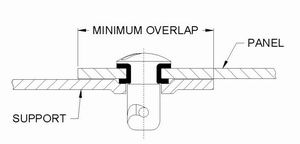

Stud Retainer Recessed in Support (support thin enough to be dimpled)

| Stud Size | Max. Support Thickness for Dimpling | Stud Hole Dia. | Minimum Overlap |

|

| 3 | .040" | 3/16" | .469" | |

| 4 | .050" | 1/4" | .625" | |

| 5 | .063" | 5/16" | .781" | |

| 65 | .078" | 13/32" | 1.02" |

| 1. Make support holes for studs and rivets. |

|

||||||||||||||||

| 2. Dimple the Support. |

|

|

|||||||||||||||

| 3. Secure Receptacle to Support. |

|

||||||||||||||||

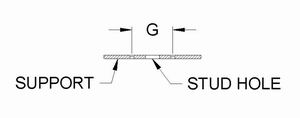

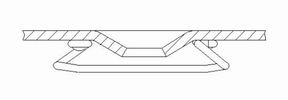

Dimpled Support Preparation for S-Spring

Receptacle

(Flush Head Stud)

| A. Dimpled Panel Stud Hole and Full Grommet | B. Dimpled and reverse-clinched panel stud hole |

|

|

Note: The S-Spring is the only ST-1200 Line receptacle that can accept a dimpled support hole as shown here.

| Spring Size | Stud Hole Dia. | Dim. G ±.002 |

Rivet Hole Dia. | Rivet Hole Countersink | Rivet Shank Dia. |

| 3 | 3/16" | .625" | .097" to .100" | 3/16" dia. x 110° | 3/32" |

| 4 | 1/4" | .750 | |||

| 5 | 5/16" | 1.000 | .129" to .133" | 1/4" dia. x 110° | 1/8" |

| 65 | 13/32" | 1.375" |

| 1. Drill support holes for studs and rivets. |

|

|||||||||||||||||||||

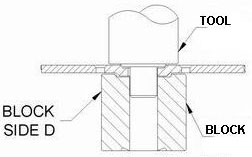

| 2. Dimple Support Hole |

|

|

||||||||||||||||||||

| 3. Secure Spring to support. |

|

|||||||||||||||||||||

| Step 2 notes: |

If the stud panel is flat on the underside and counter-sunk for the stud head on top, the support hole does not need to be dimpled. In this case, prepare the support for non-flush head studs. A panel stud hole which is dimpled for a 1276 grommet requires a different support dimple than a hole which is dimpled and reverse clinched with no grommet. |

|||||||||||||||||||||

| Use of Receptacles Other Than S-Spring | Using Flush Head studs with any ST-1200 Line receptacle, other than the S-Spring, requires that the stud hole through the panel be flat on the underside and countersunk for the stud head on top. |