PX-1600 Size 4 mm Slip-On Receptacle

| Part Number |

Finish |

| 1633-4300-Z3CT |

(Standard Finish)

|

| 1633-4300-Z3YT

Discontinued when current inventory is consumed.

|

|

| 1633-4300-Z3BT |

|

| 1633-4300-ZFBT

Discontinued when current inventory is consumed.

|

|

|

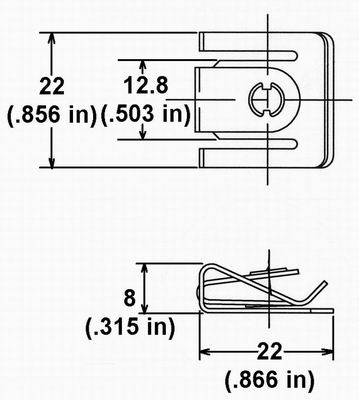

Support Range: 0.7 mm to 2.5 mm (.027 in to .100 in)

|

Material: Spring Steel

Mechanical:

Maximum Load without Distortion: 30 lb.

Maximum Torque: 23 in.-lb.

|

|

|

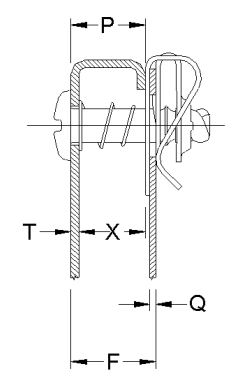

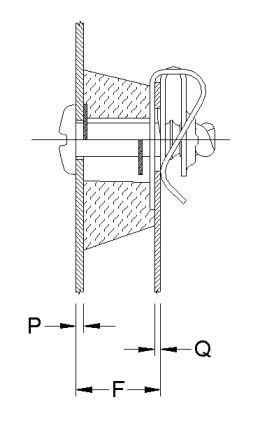

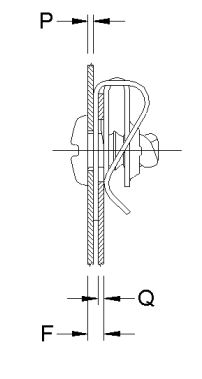

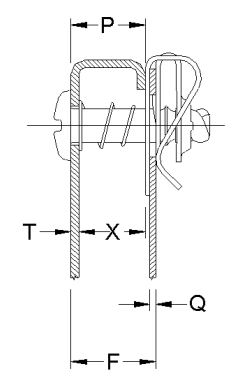

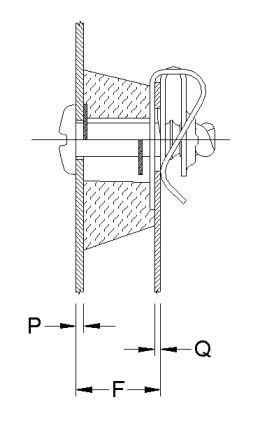

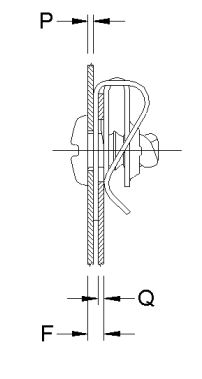

| F = P + Q + 0.7 mm (.028 in) |

F = P + Q + GASKET |

F = P + Q + 0.7 mm (.028 in) |

Calculate F Dimension

Using the table below, find the F Dimension range that applies to

your calculated F range. The "G" for the Stud Part

Number is stated to the right of the applicable F Dimension range.

| F Dimension |

"G" |

| mm |

in |

| 1.5-2.4 |

.059-.094 |

08 |

| 2.5-3.4 |

.098-.134 |

09 |

| 3.5-4.4 |

.138-.173 |

10 |

| 4.5-5.4 |

.177-.213 |

11 |

| 5.5-6.4 |

.217-.252 |

12 |

| 6.5-7.4 |

.256-.291 |

13 |

| 7.5-8.4 |

.295-.331 |

14 |

| 8.5-9.4 |

.335-.370 |

15 |

| 9.5-10.4 |

.374-.409 |

16 |

| 10.5-11.4 |

.413-.449 |

17 |

| 11.5-12.4 |

.453-.488 |

18 |

| 12.5-13.4 |

.492-.528 |

19 |

| 13.5-14.4 |

.531-.537 |

20 |

| 14.5-15.4 |

.571-.606 |

21 |

| 15.5-16.4 |

.610-.646 |

22 |

| 16.5-17.4 |

.650-.685 |

23 |

|

| F Dimension |

"G" |

| mm |

in |

| 17.5-18.4 |

.689-.724 |

24 |

| 18.5-19.4 |

.728-.764 |

25 |

| 19.5-20.4 |

.768-.803 |

26 |

| 20.5-21.4 |

.807-.843 |

27 |

| 21.5-22.4 |

.846-.882 |

28 |

| 22.5-23.4 |

.886-.921 |

29 |

| 23.5-24.4 |

.925-.961 |

30 |

| 24.5-25.4 |

.965-1.000 |

31 |

| 25.5-26.4 |

1.004-1.039 |

32 |

| 26.5-27.4 |

1.043-1.079 |

33 |

| 27.5-28.4 |

1.083-1.118 |

34 |

| 28.5-29.4 |

1.122-1.157 |

35 |

| 29.5-30.4 |

1.161-1.197 |

36 |

| 30.5-31.4 |

1.201-1.236 |

37 |

| 31.5-32.4 |

1.240-1.276 |

38 |

|

|