PX-1600 Size 4 mm Rivet-On Receptacle

| Part Number |

Finish |

| 1633-4400-Z3CT |

(Standard Finish)

|

| 1633-4400-Z3YT

Discontinued when current inventory is consumed.

|

|

| 1633-4400-Z3BT |

|

| 1633-4400-ZFBT

Discontinued when current inventory is consumed.

|

|

Material: Spring Steel

Mechanical:

Maximum Load without Distortion: 30 lb.

Maximum Torque: 23 in.-lb.

|

|

|

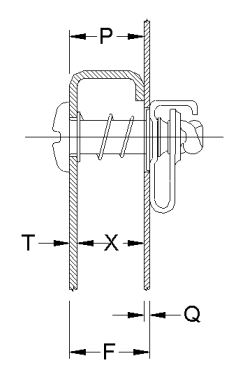

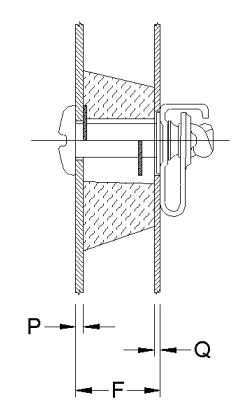

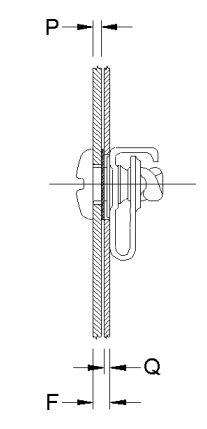

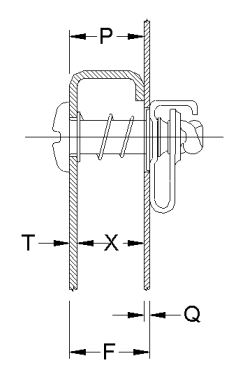

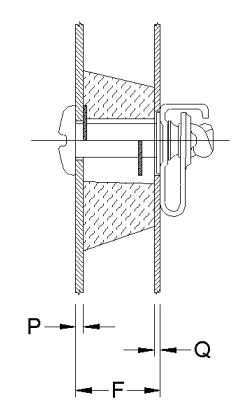

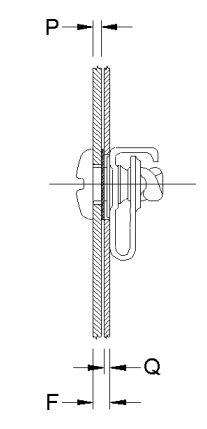

| F = P + Q |

F = P + Q + GASKET |

F = P+ Q + 0.5 mm (.02 in) |

Calculate F Dimension

Using the table below, find the F Dimension range that applies to

your calculated F range. The "G" for the Stud

Part Number needed is stated to the right of the applicable F

Dimension range.

|

4 mm Rivet Plate Receptacle Stud Selection Table

|

| F Dimension |

"G" |

| mm |

in |

| 1.0-1.9 |

.039-.075 |

08 |

| 2.0-2.9 |

.079-.114 |

09 |

| 3.0-3.9 |

.118-.154 |

10 |

| 4.0-4.9 |

.157-.193 |

11 |

| 5.0-5.9 |

.197.-232 |

12 |

| 6.0-6.9 |

.236-.272 |

13 |

| 7.0-7.9 |

.276-.311 |

14 |

| 8.0-8.9 |

.315-.350 |

15 |

| 9.0-9.9 |

.354-.390 |

16 |

| 10.0-10.9 |

.394-.429 |

17 |

| 11.0-11.9 |

.433-.469 |

18 |

| 12.0-12.9 |

.472-.508 |

19 |

| 13.0-13.9 |

.512-.547 |

20 |

| 14.0-14.9 |

.551-.587 |

21 |

| 15.0-15.9 |

.591-.626 |

22 |

| 16.0-16.9 |

.630-.665 |

23 |

|

| F Dimension |

"G" |

| mm |

in |

| 17.0-17.9 |

.669-.705 |

24 |

| 18.0-18.9 |

.709-.744 |

25 |

| 19.0-19.9 |

.748-.783 |

26 |

| 20.0-20.9 |

.787-.823 |

27 |

| 21.0-21.9 |

.827-.862 |

28 |

| 22.0-22.9 |

.866-.902 |

29 |

| 23.0-23.9 |

.906-.941 |

30 |

| 24.0-24.9 |

.945-.980 |

31 |

| 25.0-25.9 |

.984-1.020 |

32 |

| 26.0-26.9 |

1.024-1.059 |

33 |

| 27.0-27.9 |

1.063-1.098 |

34 |

| 28.0-28.9 |

1.102-1.138 |

35 |

| 29.0-29.9 |

1.142-1.177 |

36 |

| 30.0-30.9 |

1.181-1.217 |

37 |

| 31.0-31.9 |

1.220-1.256 |

38 |

|

|