PX-1600 Size 6 mm Slip-On Receptacle

| Part Number | Finish |

| 1633-6300-Z3CT |

(Standard Finish) |

| 1633-6300-Z3YT

Discontinued when current inventory is consumed. |

|

| 1633-6300-Z3BT | |

| 1633-6300-ZFBT

Discontinued when current inventory is consumed. |

|

|

|

Material: Spring Steel

Mechanical:

Maximum Load without Distortion: 50 lb.

Maximum Torque: 31 in.-lb.

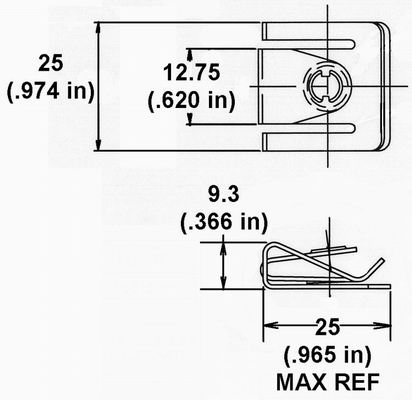

Support Range: 0.7 mm to 3.2 mm (.027 in to .126 in)

|

|

|

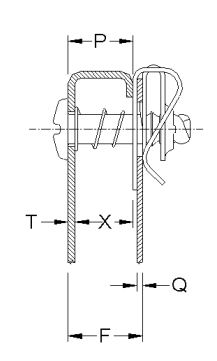

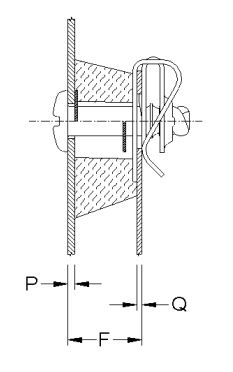

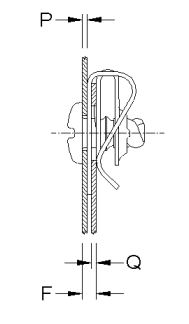

| F = P + Q + 0.8 mm (.031 in) | F = P + Q + GASKET | F = P + Q + 0.8 mm (.031 in) |

Calculate F Dimension

Using the table below, find the F Dimension range that applies to your calculated F range. The "G" for the Stud Part Number is stated to the right of the applicable F Dimension range.

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||