ST-1200 Line Size 4 Receptacle - Sealed Pressed-In

The 1219-PS Receptacles pack a durable 1/4-turn action into a compact, sealed unit.

The feel of their operation action is as crisp and solid as that of the most rugged aircraft types.

Their sealed construction prevents metal dust from fastener action from entering the enclosure and is compatible with EMI barrier design.

|

|

|

|||||||||||||||||

Note: The 1219-R4SS (Snap Ring) retainer is the only stud retainer allowing panel to support contact without requiring a nest in the panel to contain the retainer.

|

Materials: Finish: |

|

Installation:

|

|

| Specifications | |

|

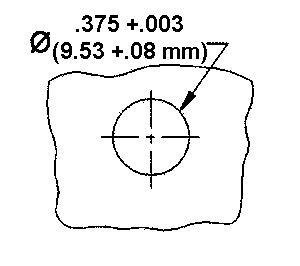

Support Hole Dia. (for receptacle insertion) |

.375 +.003/-.000 (9.53 +.08/-.00 mm) |

| Minimum Support Thickness | .050 (1.27 mm) |

| Press-in Pressure | 2700 lb |

Notes:

- These specifications are taken from test results when the receptacle is press fit into 2024T6 Aluminum.

- The press-in force should be steady rather than a sharp blow.

- Use the minimum pressure necessary to fully seat receptacle shoulder flush against the support. The required pressure should be determined by testing.

- Do not exceed 3000 lb pressure.

- Observe installation procedures normal for standard self-clinching nuts.

Stud Selection

| Material Thickness (Panel + Gap + Support) |

Use Size 4 stud with following Grip Length |

Use 1219-PS4 |

|

| inch | mm | ||

| .035-.059 | .89-1.50 | 40 | -2-Z3CT |

| .060-.084 | 1.52-2.13 | 40 | -1-Z3CT |

| .085-.109 | 2.16-2.77 | 45 | -2-Z3CT |

| .110-.134 | 2.79-3.40 | 45 | -1-Z3CT |

| .135-.159 | 3.43-4.04 | 50 | -2-Z3CT |

| .160-.184 | 4.06-4.67 | 50 | -1-Z3CT |

| .185-.209 | 4.70-5.31 | 55 | -2-Z3CT |

| .210-.234 | 5.33-5.94 | 55 | -1-Z3CT |

| .235-.259 | 5.97-6.58 | 60 | -2-Z3CT |

| .260-.284 | 6.60-7.21 | 60 | -1-Z3CT |

| .285-.309 | 7.24-7.85 | 65 | -2-Z3CT |

| .310-.334 | 7.87-8.48 | 65 | -1-Z3CT |

| .335-.359 | 8.51-9.12 | 70 | -2-Z3CT |

| .360-.384 | 9.14-9.75 | 70 | -1-Z3CT |

| .385-.409 | 9.78-10.39 | 75 | -2-Z3CT |

| .410-.434 | 10.41-11.02 | 75 | -1-Z3CT |

| .435-.459 | 11.05-11.66 | 80 | -2-Z3CT |

| .460-.484 | 11.68-12.29 | 80 | -1-Z3CT |