Stud Panel Preparation

for Flush Head Studs

Flush Head Studs

Panel Preparation for 1276 Grommet

Installation of a 1276 Full Grommet Retainer is a multi-step

process and requires several different tools.

|

Flush Head Stud using type 1276 Full Grommet Retainer

|

| 1. Drill Hole |

| Stud Size |

Hole Diameter |

| 4 |

17/64" |

| 5 |

5/16" |

| 6 |

3/8" |

| 65 |

7/16" |

| 7 |

15/32" |

|

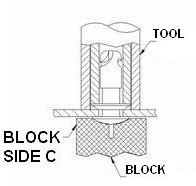

2. Dimple Hole |

| Stud Size |

Tool Part Number |

Block Part Number |

| 4 |

9916-1-64-BB |

9902-1-64-BB |

| 5 |

9916-1-65-BB |

9902-1-65-BB |

| 6 |

9916-1-66-BB |

9902-1-66-BB |

| 65 |

9916-1-665-BB |

9902-1-665-BB |

| 7 |

9916-1-67-BB |

9902-1-67-BB |

|

|

| 3. Install Grommet |

|

| 4. Set Grommet |

| Stud Size |

Tool Part Number |

Block Part Number |

| 4 |

9916-3-64-BB |

9902-3-64-BB |

| 5 |

9916-3-65-BB |

9902-3-65-BB |

| 6 |

9916-3-66-BB |

9902-3-66-BB |

| 65 |

9916-3-665-BB |

9902-3-665-BB |

| 7 |

9916-3-67-BB |

9902-3-67-BB |

|

|

| 5. Insert Stud and Clinch Stud |

| Stud Size |

Block Part Number |

| 4 |

9902-3-64-BB |

| 5 |

9902-3-65-BB |

| 6 |

9902-3-66-BB |

| 65 |

9902-3-665-BB |

| 7 |

9902-3-67-BB |

|

|

|

Note:

Dimpled Panels require Dimpled Supports.

|

Panel Preparation for Reverse Clinched Hole

(No Stud Retainer)

Installation in a dimpled and reverse-clinched panel stud

hole is a multi step process.

| 1. Drill Hole |

Stud

Size |

Hole

Dia. |

MAX Panel Thickness

for Dimpling |

| 3 |

9/64" |

.030" |

| 4 |

13/64" |

.040" |

| 5 |

15/64" |

.050" |

| 65 |

21/64" |

.078" |

|

| 2. Dimple Hole |

Stud

Size |

Tool Part Number |

Block Part Number |

| 3 |

9916-1-6-N3-BB |

9902-1-6-N3-BB |

| 4 |

9916-1-6-N4-BB |

9902-1-6-N4-BB |

| 5 |

9916-1-6-N5-BB |

9902-1-6-N5-BB |

| 65 |

9916-1-6-N65-BB |

9902-1-6-N65-BB |

|

|

| 3. Insert Stud |

|

| 4. Clinch Stud |

Stud

Size |

Block Part Number |

| 3 |

9902-3-6-N3-BB |

| 4 |

9902-3-6-N4-BB |

| 5 |

9902-3-6-N5-BB |

| 65 |

9902-3-6-N65-BB |

|

|

|

Note:

Dimpled Panels require Dimpled Supports.

|

Panel Preparation for 1219-R, 127H, and 127P

| 1. Drill and countersink holes |

| Stud Size |

Dim. A

+.010"

-.000" |

Dim. B

+.010"

-.000" |

Dim. C

+.010"

-.000" |

| 3 |

.367" |

.188" |

.051" |

| 4 |

.508" |

.250" |

.074" |

| 5 |

.633" |

.313" |

.092" |

| 65 |

.757" |

.407" |

.095" |

|

|

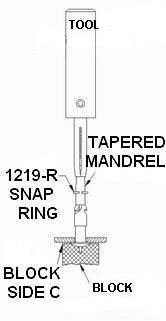

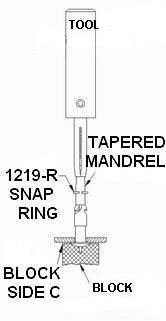

2. Install stud retainer

1219-R and 127P Retainer Installation

9906-RS HAND TOOL is used to push the retainer over a

Tapered Mandrel (included) and over the cam end of the stud

until it reaches the undercut. Once the retainer reaches the

undercut, it snaps back to its original size and prevents

the stud from coming out of the panel.

Any flat block may be used to support the Flush Head

Stud while the retainer is attached.

|

1. Place the stud head on the support

and place the stud through the panel.

Use a Flat Surface Plate in place of the block.

|

|

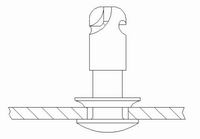

| 2. Place the retainer on mandrel. |

|

| 3.Align ring or spring ends so that they will miss the stud cam. |

|

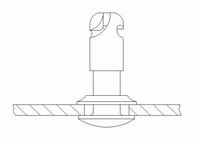

| 4. Place the mandrel in end of stud cam and place the tool over mandrel |

Stud

Size |

Tool Part Number |

| 3 |

9906-RS-3-BB |

| 4 |

9906-RS-4-BB |

| 5 |

9906-RS-5-BB |

| 65 |

9906-RS-65-BB |

|

| 5. Push retainer until it is seated in the stud undercut. |

|

|

1219-R

Snap Ring

|

127P

Push-on Grommet

|

127H Half Grommet Retainer installation

|

|

Note:

This stud panel hole permits use of S-Spring receptacles

without a dimpled stud hole in support.

|

Panel Preparation for 127S-F

Thick Panel Grommet Retainer

Installation of a 127S-F Thick Panel Grommet Retainer is also

a multi-step process and requires several different tools.

|

1. Make hole in panel for grommet press fit, then countersink

and counter bore.

|

| Stud Size |

Dim. A |

Dim. B |

Dim. C |

| 3 |

.328" |

.219" |

.030" |

| 4 |

.453" |

.313" |

.043" |

| 5 |

.578" |

.375" |

.045" |

|

|

|

2. Press grommet/stud assembly into hole

|

|

3. Flare grommet using flaring tool.

|

| Stud Size |

Flaring Tool

Part Number |

| 3 |

9906-A-3-BB |

| 4 |

9906-A-4-BB |

| 5 |

9906-A-5-BB |

|

|

|

4. Flatten grommet using tool.

|

| Stud Size |

Tool Part Number |

| 3 |

9916-3-13-BB |

| 4 |

9916-3-14-BB |

| 5 |

9916-3-15-BB |

|

|

|

Note:

This stud panel hole permits use of S-Spring receptacles

without a dimpled stud hole in support.

|

|