Quarter Turn - PA-3500 Line

Manufactured in the United States of America! |

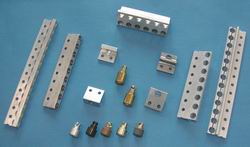

Captive quarter-turn stud assemblies with multiple hole receptacle rails.

|

On-Line Product Selector

|

- Type 3506-SC stud assemblies consist of a stud and coil spring captive in a steel cup. The assemblies are installed by flaring the end of the cup neck into a countersunk panel hole. Stud locking action compresses the spring, exerting a clamping force on the fastened parts. In locking, the stud spiral cam engages a rigid wire which is offered by the receptacle. MIL-F-25173A* approved.

- Type 3522-S stud

assemblies provide a nearly solid lock without allowing the sheet

separation that occurs with 3506-SC assemblies while under

tensile overload sufficient to overcome the expansion force of

their springs. With 3522-S assemblies, the stud cam first

quarter-turns onto the receptacle wire under spring tension

supplied by a curved washer. Further locking rotation then starts

to turn the cammed fastener head around a stud cross-pin. The

head is moved downward as it turns, compressing a coil spring

which is stronger than the curved washer, and finally compressing

the curved washer flat. At the fully-locked position, the assembly

has no remaining spring movement achievable by tensile overload.

3522-S assemblies are not MIL-F-25173A approved.

CAUTION: Any external factor that prevents the stud from turning with initial locking torque could allow the fastener head to rotate first. This could convey an erroneous impression of locking while the stud cam has not locked onto the receptacle wire. All operators of this special purpose fastener should be trained to recognize proper stud cam locking.

- Standard receptacles The PA-3500

Line receptacles come in both single hole and strip

configurations. The strip configuration acts as a supporting

frame for the panels or removable parts to be fastened, with

continuous holes for stud engagement and rivet mounting on

3/8" centers. The strip is riveted to a support member and

the stud panel rests against the strip face having the stud

holes. The strips are aluminum alloy with a continuous rigid

stainless steel wire staked across the underside of the stud

holes. The fastened panel rests on the strip and its captive

quarter-turn studs engage the rigid wire.

Custom cut lengths of 3590 and 3595 strips may be specially ordered. The part callout system for cut lengths assumes standard hole spacing and location of the holes at each end at the standard distance from the end.

* Meets the design, physical and performance requirements of MIL-F-25173A. However, full mechanical properties testing may not be performed on each production lot.